Product Center

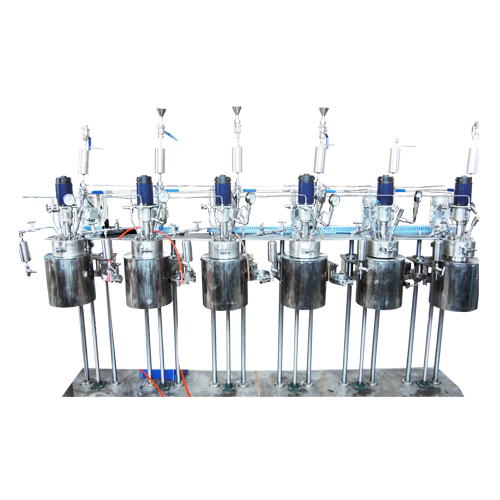

Your Current Location:Home > Product CenterThe heating method of the reaction kettle is jacketed heat-conducting oil circulating heating, equipped with heat-conducting oil heating oil furnace and hot oil circulating pump, under the condition of PID program temperature control, to achieve stable heating and cooling in the kettle.

Weihai Zhengwei Machinery Co., Ltd. is a high-tech enterprise integrating complete independent research and development, manufacturing, and marketing systems. It can provide special customized design and manufacturing according to the volume, working temperature, and working pressure provided by customers.

Shale oil is a brown, viscous liquid product produced by thermal decomposition of organic matter during oil shale dry distillation.

In the context of the shortage of oil resources, oil shale, as a rich resource, has received more and more attention.

Shale oil generally contains more impurities, which has a great impact on its further processing and utilization.

Hydrogenation, as a very important means of removing impurities and improving product quality in petrochemical production, is undoubtedly the preferred process for processing shale oil.

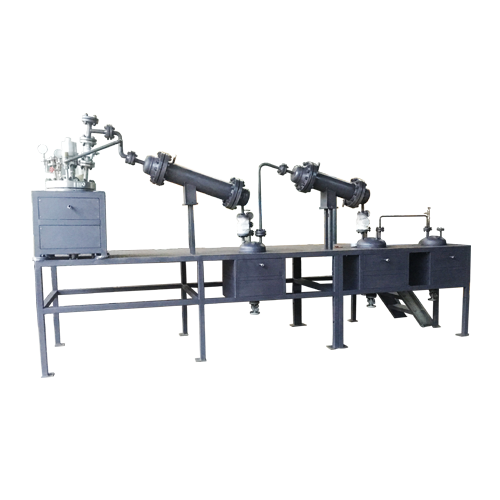

Distillation is a thermodynamic separation process. It uses the different boiling points of the components in the mixed liquid or liquid-solid system to evaporate the low-boiling components, and then condense to separate the entire components. There are two types of unit operations: evaporation and condensation. Union of unit operations. Compared with other separation methods, such as extraction, filtration and crystallization, its advantage is that it does not need to use other solvents other than system components, so as to ensure that no new impurities are introduced.

Our company has specially customized distillation system for the old village chief wine industry. The whole set of equipment adopts food-grade stainless steel accessories and mirror polishing. This set of equipment can obtain higher concentration of alcohol.

The broad understanding of the reactor is a container with physical or chemical reactions. Through the structural design and parameter configuration of the container, the heating, evaporation, cooling and low-speed mixing functions required by the process are realized.

Metallurgical reactors are widely used in the metallurgical industry. Wear-resistant stainless steel is used inside, which can withstand various harsh materials and reaction conditions.

Weihai Zhengwei Machinery Co., Ltd. is a high-tech enterprise integrating complete independent research and development, manufacturing, and marketing systems. It can provide special customized design and manufacturing according to the volume, working temperature, and working pressure provided by customers.